At a Glance

| Principal Activity(ies): |

|

| Location(s): | Manufacturing facilities in Bayan Lepas, Penang and Kulim, Kedah, Malaysia |

| Number of Employees: | 250 |

| Manufacturing Floorspace: | 100,000 sq. ft. |

| Revenue (2022): | RM50 million |

| Certificate(s): |

|

| Core Competency(ies): |

|

| Website: | http://www.gf-technology.com/ |

| Contact Person: | Sahidah Awang, Wong Kwok Liang, Khor Meow Siang Email: info@gf-technology.com |

Introduction

Incorporated in 1994, GF Technology, being the subsidiary of GF Group, focuses on the design and manufacturing of industrial grade optical filters and optical coatings on plastic and glass substrates such as AR (Anti Reflective), HC (Hard coating), and Anti Smude Coating. The company’s coating capabilities include tooling fabrication, a wide range of secondary processes that include vacuum coating process, 2K mould design, precision tempo printing and silkscreen printing.

The company’s core business ranges from industry applications to life science and medical applications, consumer mobility and wearables as well as automotive applications.

Products & Services

1. Optical Filters

GF Technology can design and fabricate sophisticated optical filter with nano accuracy. Among the optical filters produced include bandpass filters, long wave pass filters, short wave pass filters, notch filters, multiband pass filters, and multi-notch filters with high OD (Optical Density) requirements.

2. Fluorescent Filter

High-performance fluorescence filter sets for a range of fluorescence applications, including flow cytometry, PCR, and others. To generate high-contrast pictures and to increase signal-to-noise ratios, these hard-coated ULTRA Series excitation filters and emission filters are designed with tight wavelength control, steep edges, high transmission, and higher than OD6 blocking. The dichroic filters have sharp edges, high transmission, and high reflection built into their construction. Each filter set in the ULTRA Series is designed to have a zero pixel shift and a small transmitted wavefront error (TWE). There are available single-band and multiband filter sets.

3. Plastic Coating

In order to successfully offer coatings on plastics, such as Zeonex, Ultem, and high-index OKP materials with optical thin films that can fulfill the environmental requirements of current MIL-SPECs and ISO specifications, GF Technology has developed multiple coating process. Abrasion, humidity, Xenon light Testing and multiday temperature cycling are examples of common tests. The company has created a variety of coating for use in applications ranging from the visible to the infrared, including wide-angle AR coatings, beamsplitters, and dielectric mirrors.

4. Beam Splitters Combiners

This particular product series offers curves for beam splitters, combiners, dichroic beam splitters, RGB colour combiners, and polarizers. It is best suited for separating beams, combining beams, or acting as p and s polarisation. Design particularly for XR, AR, and other related technologies.

5. Multicomponent Plastic Injection

GF Technology is capable of fabricating 2K and 3K tooling for plastic injection. The company also provides plastic injection services for customers and a variety of secondary processes such as VM (Vacuum Metalizing), AR Coating on plastic, spraying, tempo silkscreen, assembly process, and ultrasonic welding process. GF Technology has a total of 46 plastic injection machines with 8 units of 2K and 3K injection machines and single-shot machines ranging from 18 tons to 320 tons.

6. World-class Testing Facilities

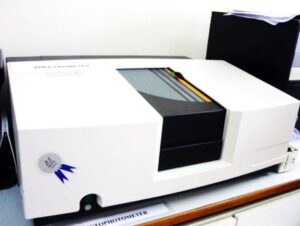

GF Technology has a laboratory centre to conduct various customer reliability tests. The lab consists of equipment such as Spectrophotometer, FTIR (Fourier Transform Infrared Spectroscopy), Laser Interferometer, MFI (Melt Flow Index), Temperature Cycling Chamber, Humidity Chamber, Xenon Light Tester, QUVT (UV tester) and Colour Balance tester, among others.

|

|

|

Spectrophotometer |

Humidity Chamber |

|

|

|

QUV Tester |

UMA Spectrophotometer |

|

|

|

Xenon Light Tester (Q-Sun XE-2) |

Fourier Transform Infrared (FTIR) |

Written in Jan 2023

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.