AllianceCorp Manufacturing Sdn Bhd

At a Glance

| Principal Activit(ies): | We provide development, process automation and end-to-end manufacturing solutions for high qualified buy parts, devices, mechatronics modules and complete equipment build involving complex machining, welded frame, orbital welding, cleanroom assembly and system integration & test. |

| Location(s): | 2006 Jalan Jelawat, Seberang Jaya Industrial Estate, 13700 Prai, Penang.

Other locations: Kedah, Malaysia; Changsu, China; Ulft, Netherlands; Olomouc, Czech Republic; Oregon, United States; Singapore; Andover, United Kingdom |

| Number of employees: | 1200+ |

| Manufacturing Floorspace: | 690,000 sq. ft. |

| Core Competency(ies): |

|

| Revenue: | RM534 million (2022) |

| Certification (s): | ISO 9001: 2015 ISO 14001: 2015 ISO 13485 ISO 27001 |

| Website: | https://www.acm-holdings.com/ |

| Contact Person: | Jos Willaert Email: jos.willaert@acm-holdings.com LM Saw Email: lm.saw@acm-hodings.com |

Introduction

AllianceCorp Manufacturing (“ACM”) began its global journey in 1998 with its flagship subsidiary, Alliance Contract Manufacturing founded in Penang, Malaysia. ACM manufactures advanced components, modules and system integration for consumer devices and high-tech equipment manufacturers in domains including medical/life science, semiconductor/E&E, professional printing/imaging, electric vehicles/energy, and e-commerce/e-logistics.

With five manufacturing sites and four engineering centres across Asia, Europe, and the United States, ACM helps more than 40 OEMs and OBMs to make their products and complex machines and delivered to their desired destinations.

Products & Services

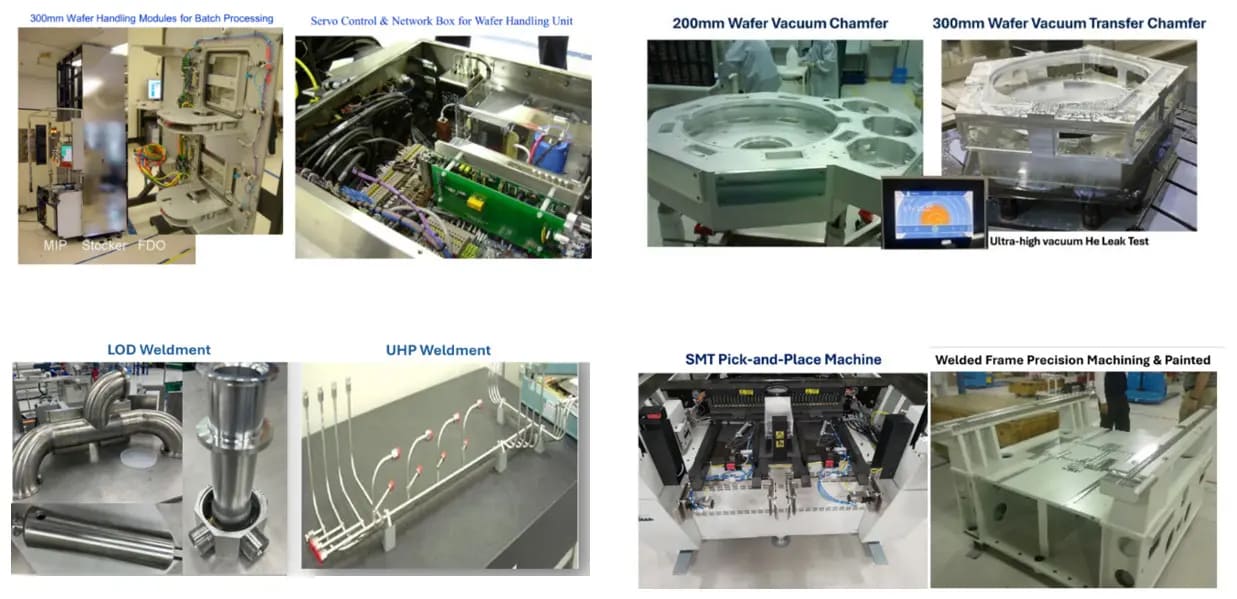

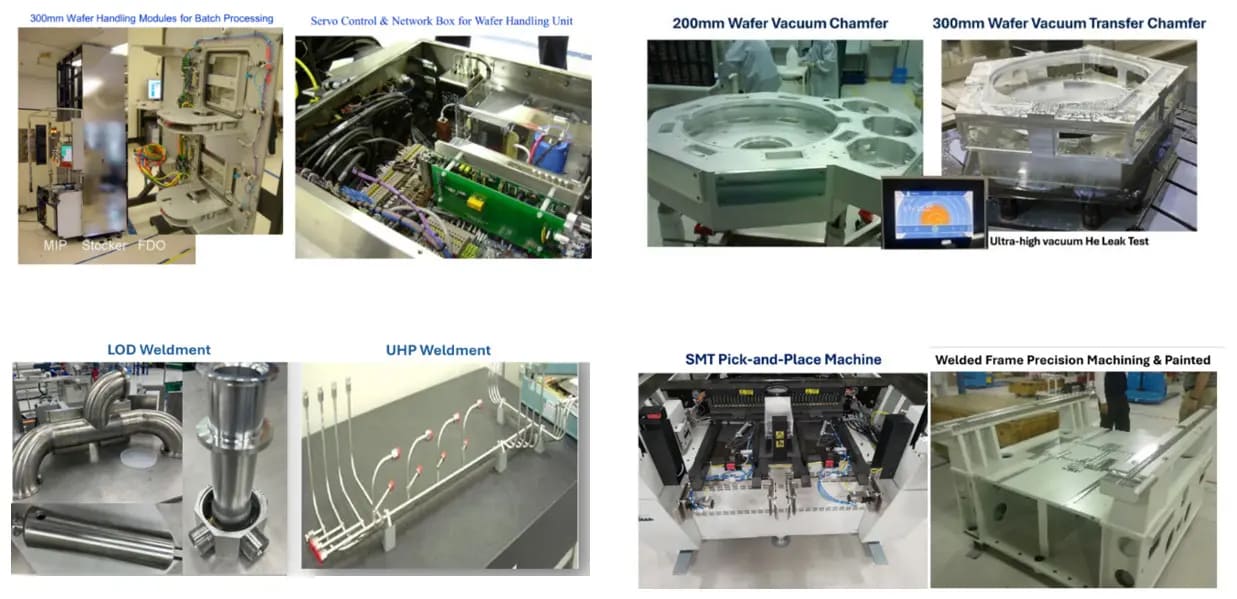

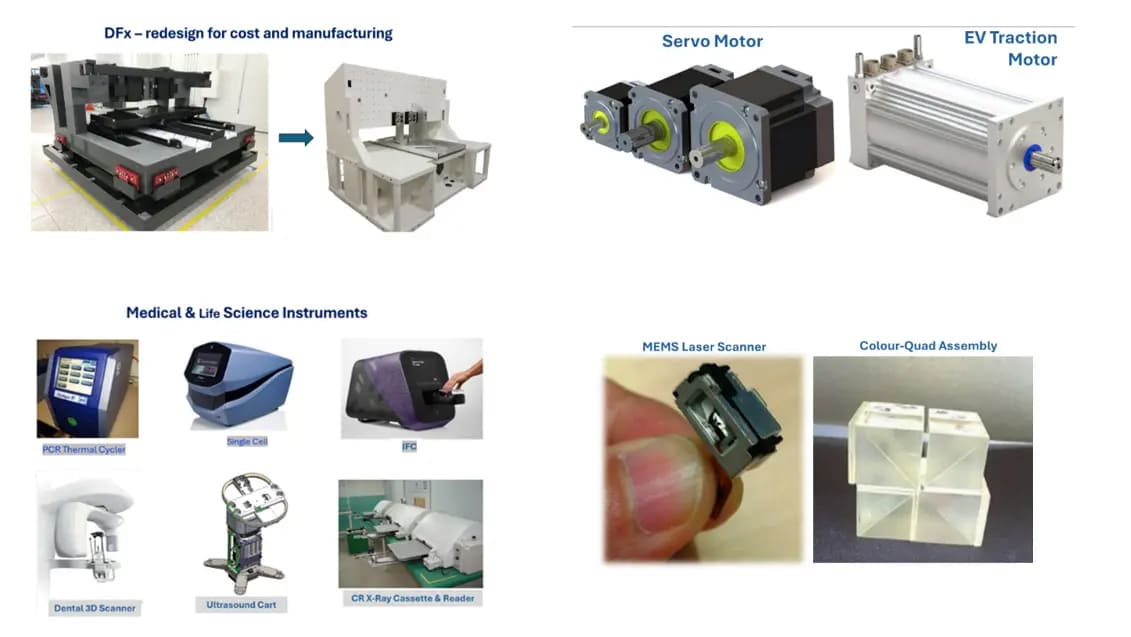

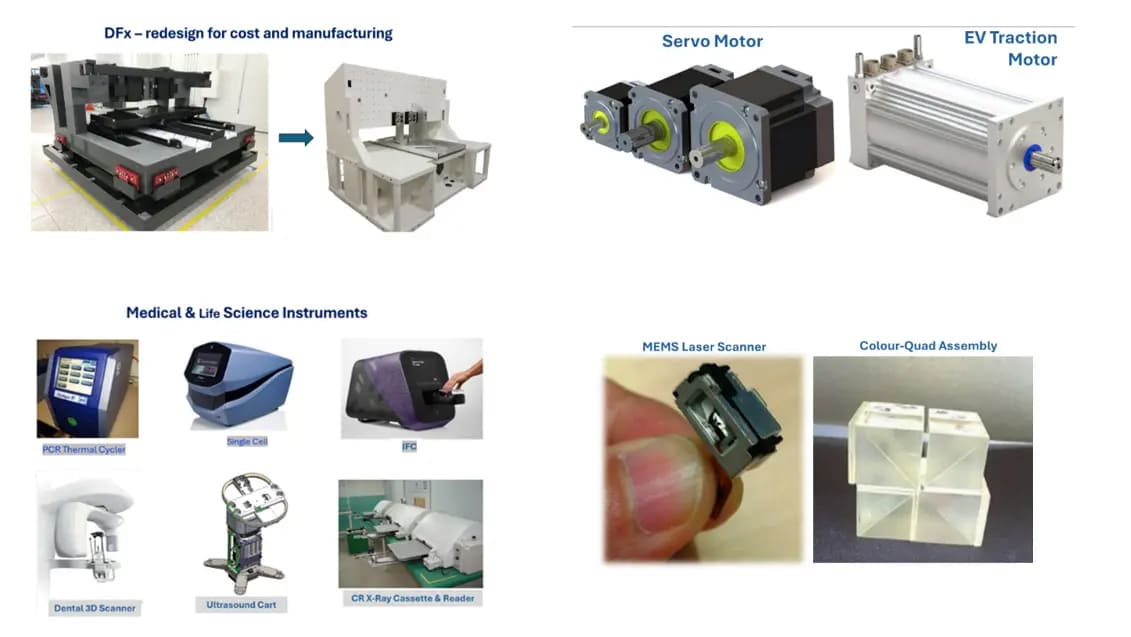

ACM, in conjunction with its supply chain partners deliver design, manufacturing and process automation solutions to its customers. ACM brings value analysis & value engineering with its expertise on (electro)mechanical designs, together with its understanding and experience in manufacturing processes. With its diverse machining, fabrication, special processes for ultra-precision surface finishing, high vacuum leak test, orbital welding, and secondary processes in surface treatment, painting, etc. coupled with control room, class 1K & 100 cleanroom assembly and test, ACM addresses the sourcing and manufacturing needs for their customers. ACM’s expertise in parametric testing combined with their extensive ERP (SAP), MOM (ACMView) and supply chain management enables the company to integrate manufactured parts to full system builds if required.

Some OEM Products

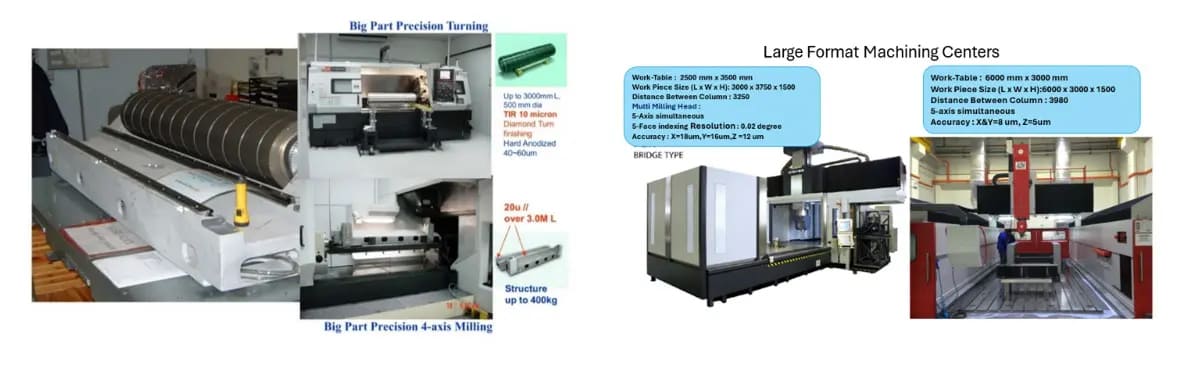

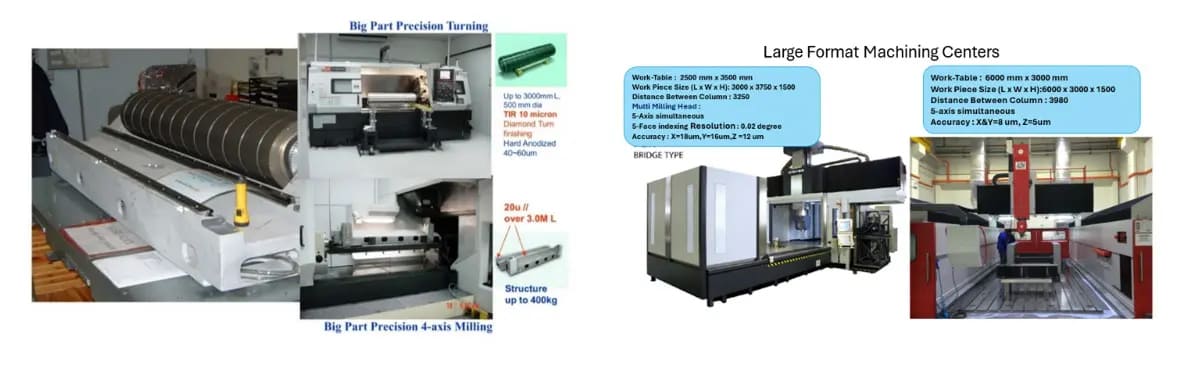

Some Manufacturing Assets

Future Plan

ACM is expanding its operations to cater for growth. The company recently opened an additional plant in Kedah, Malaysia with a total investment of RM180m focused on mid-to-large format parts and assembly for the semiconductor equipment market.

ACM Penang also earmarks 9.5-acre land next to its current main site for future expansion, with the possibility of adding 550,000 sf manufacturing and office space in next 3 to 5 year.

Written in April 2024

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.