At a Glance

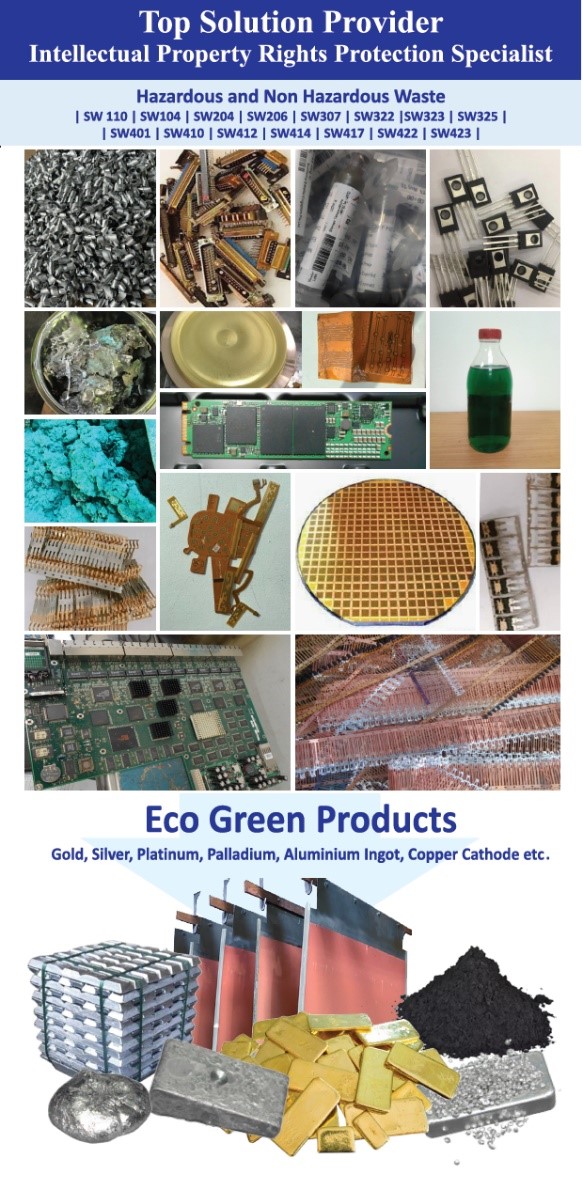

| Principal Activity (ies): | Scheduled & non-scheduled waste management protecting intellectual property rights and promote close loop, focusing primarily in Platinum Group Metals (PGM) recovery & refining, manufacturer of secondary aluminium alloy ingot, copper recovery & refining and hazardous liquid waste recovery |

| Location(s): | Integrated Waste Management plants in Penang (HQ), Selangor, Johor, Sarawak |

| Number of Employees: | 650 |

| Manufacturing Floorspace: | 250,750 sqft |

| Revenue (2021): | RM384,600,000 |

| Certificate(s): |

|

| Core Competency (ies): |

|

| Website: | www.shanpoornammetals.com |

| Contact Person: | Rose Kuan Email: rose_kuan@ensspm.com ; enquiry@ensspm.com |

Introduction

Shan Poornam Metals (SPM), Malaysian homegrown waste recovery and refining company, is the pioneer and leader in hazardous waste management. Incorporated in 1960, it started as a waste collection centre and has evolved into a regional leader in industrial waste management companies with Environmentally Sound Management (ESM) facility, promoting closed-loop recycling.

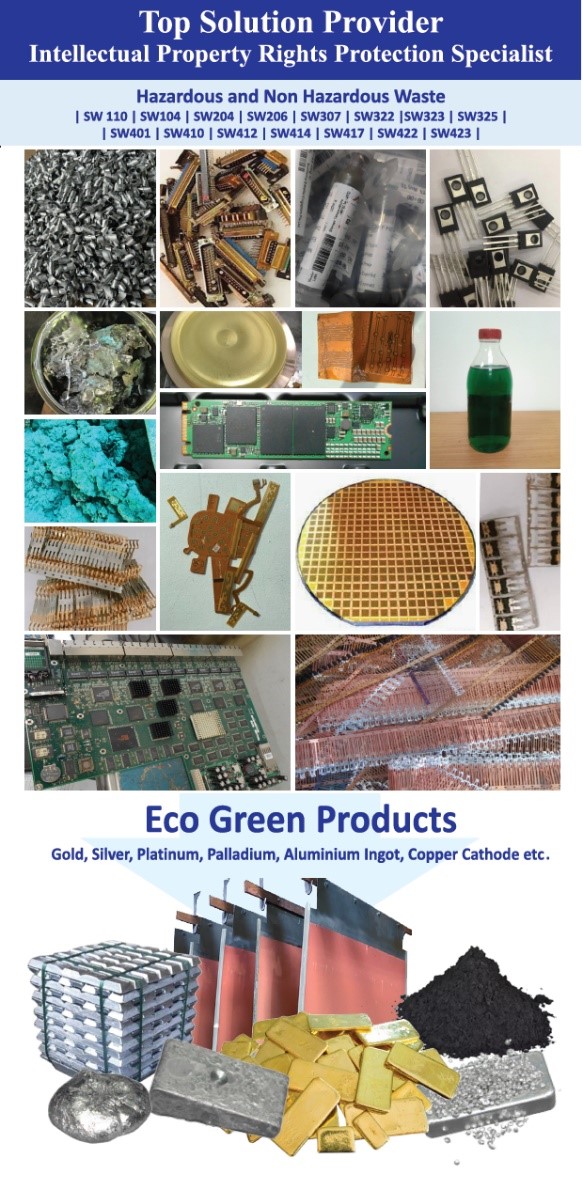

Equipped with eco-green technology, backed by an innovative R&D team, the plant can process industrial solid and liquid waste into precious metals such as gold, silver, platinum, palladium, secondary aluminium alloy ingots and copper cathode. Adopting the 5R’s Green Concept of Reduce, Reuse, Recycle, Recover and Refining, this plant produces eco-green products under SPM’s eco label “ENS” (Environment, Nature, and Society).

Positioning itself as the link between industries, consumers and environment, with strong commitment to protecting intellectual property rights – from converting e-waste to raw materials to IT asset management and disposition, SPM is the first prescribed premise licensed by the Department of Environment, Malaysia to manage metal chips and articles contaminated with spent coolant.

SPM’s business objectives are strongly aligned to the United Nation’s Sustainable Developmental Goals and it plays a pivotal role in its drive and focus on environmental stewardship. SPM’s customers range across industries, including semiconductor, Electrical & Electronics, Technology Hardware, Computer Storage, Automotive, Telecommunication, Banking, Automation, Oil & Gas, Healthcare & Medical Equipment, Consumers

Products & Services

1. Scheduled & Non-Scheduled Waste Management

SPM specialises in transforming solid and liquid waste into eco-green products which can be ploughed back into the raw material supply chain pool, and subsequently manufacture into a new product. The company protects intellectual property rights and promotes close loop supply chain in line with Sustainable Development Goal #12, focusing primarily in Platinum Group Metals (PGM) recovery & refining, manufacturer of secondary aluminium alloy ingot, copper recovery & refining and hazardous liquid waste recovery meeting international standards.

2. Secondary Aluminium Alloy Ingots (JIS, British and US standards)

SPM’s management strategy, driven by urban mining, processes rejected resources, produces raw material for manufacturing. The company is the 1st prescribed premise licensed by DOE to manage metal chips and articles contaminated with spent coolant under Schedule Waste Code 422. The patented furnaces are designed to conserve energy while using natural gas. It manufactures high-grade secondary Aluminium Alloy ingots which meet international standards.

3. Copper Cathode

SPM’s Copper Smelting furnace is designed to extract optimally copper and precious metals from electronic scrap and e-waste. The company’s smelting technology runs on renewable energy known as waste-to-energy with Clean Gas System. Its customised equipment is designed to optimise yield and produce high purity of Copper Cathode and precious metals such as gold, platinum, palladium and silver. The by-product of this process is called slag which is used as an aggregate in the construction industry.

4. Surface Cleaning

SPM offers surface cleaning adhering to stringent cleaning standards under heavily regulated environmental conditions. The optimised combination of physical, mechanical and chemical mechanisms using customised chemicals allows the company to effectively remove the sputtered materials on the components and support 24/7 process-kits recycling management. Its wide range of equipment and tools allows the company to define a flexible process flow for customers. Through SPM’s R&D team, the company continuously strives for the next generation of sputtered materials removal and optimal recovery of precious metals while extends the life span of the process kits and ensures zero contamination.

5. Information Technology Asset Disposition (ITAD)

SPM offers IT Asset Disposition service with secure asset audit, functionality test, data sanitisation and refurbishing where it can either be returned to the customer for deployment or remarket purposes. The full range of data sanitisation are:

- Data erasure: A software-based method of securely wiping data from any data storage device using zeros and ones onto all sectors of the device.

- Physical destruction: A process of degaussing, shredding and crushing for those data storage devices which are not allowed for reuse.

SPM offers decommissioning and relocation services on servers, server rack and configuration. The company maximises customers’ options and return on re-marketable assets compliant with electronic waste disposal environmental policy, secures data with auditable chain-of-custody.

Achievements & Awards

| No | NAME OF RECOGNITION | NAME OF AWARDING BODY | YEAR |

| 1 | Industry Excellence Awards 2010 | Ministry of International Trade and Industry (MITI) | 2010 |

| 2a | Prime Minister’s Hibiscus Award 2010/2011 – Notable Achievement in Environmental Performance | Ministry of Natural Resources and Environment | 2010/2011 |

| 2b | Prime Minister’s Hibiscus Award 2010/2011 – Special Project Award | Ministry of Natural Resources and Environment | 2010/2011 |

| 3 | Recognized Articles | ISRI “Sept/Oct 2011” & Media “New Straits Times” | 2011 |

| 4 | GreenTech Manufacturer Award 2012 – Gold | Ministry of Energy, Green Technology and Water (KeTTHA) | 2012 |

| 5 | Corporate Social Responsibility Leadership Awards 2012 | GMB Malaysia / Young Entrepreneur Organization Malaysia | 2012 |

| 6 | Global Leadership Awards 2013 – Renewable Energy Sector | The Leaders International | 2013 |

| 7 | 4th Middle East Business Leaders Awards 2013 – Leadership in Renewable Energy & Technology | Federation of GCC Chambers and The Leaders International | 2013 |

| 8 | Penang Green Office | Penang Green Council | 2013-2015 |

| 9 | Global Leadership Awards 2014 – Excellence in Environmental Sustainability | The Leaders International | 2014 |

| 10 | International Award for Excellence and Leadership (Madrid, Spain) | Global Trade Leaders’ Club | 2015 |

| 11 | Star Outstanding Business Awards 2015 Best Green Initiative – Gold Award |

Star Media Group | 2015 |

| 12 | Star Outstanding Business Awards 2015 Best Innovation – Platinum Award |

Star Media Group | 2015 |

| 13 | SMEs Best Brands™ Award Corporate Branding – Green Renewable Energy |

The Brand Laureate™ | 2015-2016 |

| 14 | Highest Volume E-waste Collection Award (Recovery & Refining Facility Category) | Department of Environment (DOE) Malaysia | 2021 |

| 15 | Industry Excellence Awards | PIKOM WCIT 2022 / TechFest 2022 |

2022 |

Written in Oct 2022

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.