Penchem Technologies Sdn. Bhd.

At a Glance

| Principal Activity(ies): | Research, design, synthesis, customization and manufacturing of advanced adhesives, thermal management materials and electro-magnetic interference materials for electronic, semiconductor, optical communication, military, aerospace and automotive industries. |

| Location(s): | Bukit Minyak Industrial Park, Penang, Malaysia |

| Number of Employees: | 62 |

| Manufacturing Floorspace: | 48,000 sq. ft. |

| Revenue (2021) | RM10 million |

| Certification(s): |

|

| Core Competency(ies): | Advanced material systems and solutions, including:

|

| Website: | www.penchem.com |

| Contact Person: | Email: enquiry@penchem.com |

Introduction

Located in Penang, Malaysia, Penchem Technologies, a subsidiary of Frencken group, is a key manufacturer of advanced materials and solution provider to the electronic and automotive industries. Since its establishment in 1999, Penchem’s innovation has expanded into providing superior solutions with a diverse range of advanced material products. These include optical adhesives, LED SMC, LED epoxies, B-stage adhesives, flexible epoxies, thermal conductive materials, silver electrical conductive pastes, actively aligning UV adhesives, fast cure UV adhesives, low temperature curable epoxy, gap filling silicone, thermally resistance epoxy and customized technology products.

Serving customers in the optoelectronic, semiconductor, optical communication, automotive, general electronic and green bio base materials industries, Penchem’s tailor-made solutions are of high qualities, enabling customers to build the technology of today and tomorrow.

Products

| Product Category | Special Features & Applications |

|

Optoelectronic

|

Special Features:

Applications: |

|

Semiconductor

|

Special Features:

Applications: |

|

Optical Communication

|

Special Features:

Applications: |

|

Automotive

|

Special Features:

Applications: |

|

General Electronic

|

Special Features:

Applications: |

|

Green Bio Base Materials

|

Special Features:

Applications: |

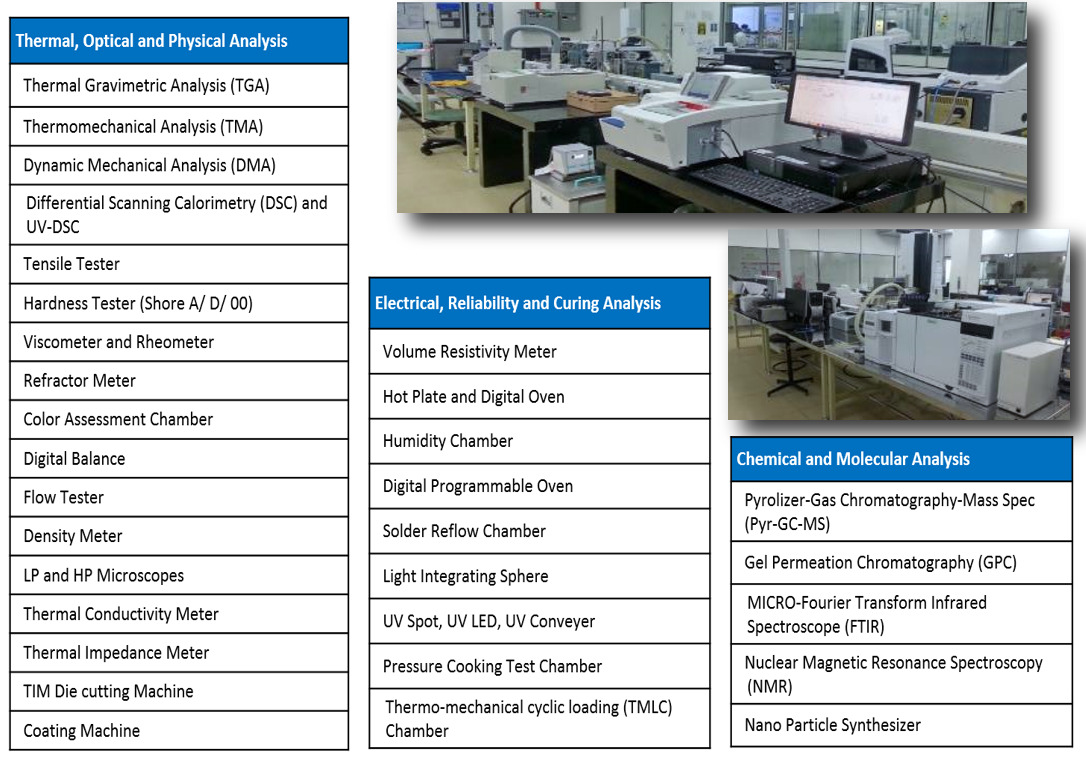

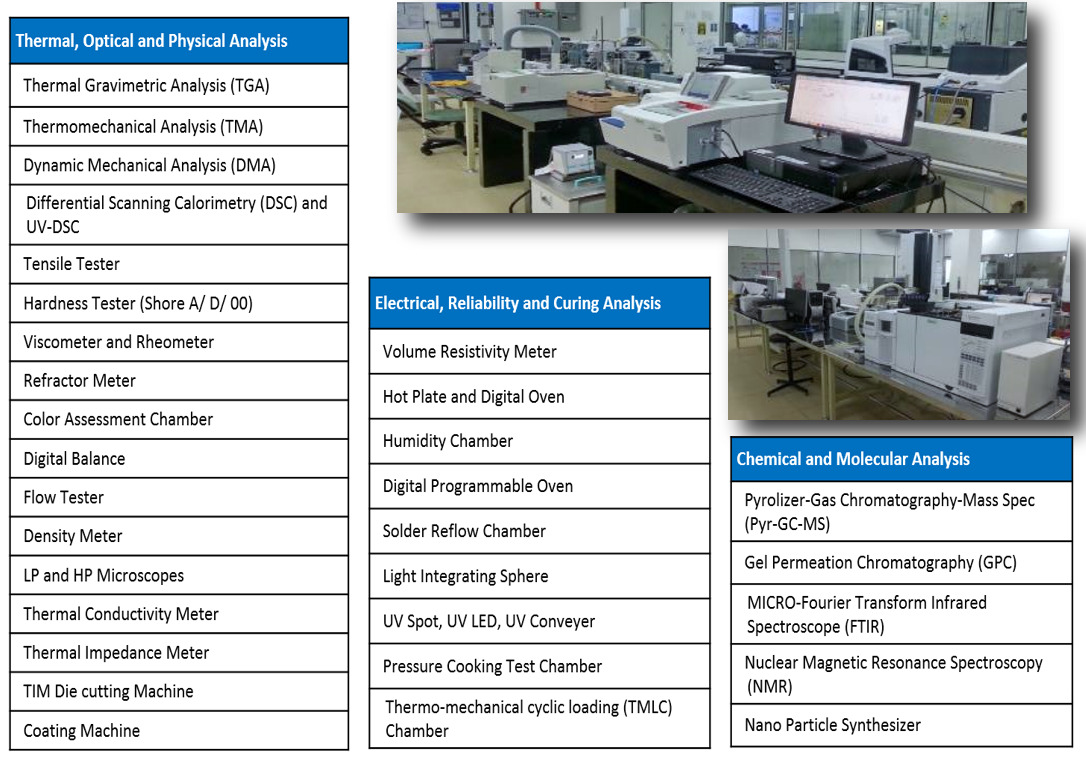

Analytical Services

Achievement & Awards

- Quality Management Excellence Award (2011) for Category 1 from Ministry of International Trade and Industry (MITI), Malaysia

- Most Innovative SME 2012 Award (2012) from Ministry of International Trade and Industry (MITI), Malaysia

- Most Innovative SME 2012 Award for Manufacturing Category (2012) from Ministry of International Trade and Industry (MITI), Malaysia

- 1-InnoCERT AAA Business Certification (2012) from Ministry of International Trade and Industry (MITI), Malaysia

- Enterprise 50 Award (2013) from SME Corporation Malaysia and Deloitte Malaysia

- Finalist for FMM Excellence Award (2013) from Federation of Malaysian Manufacturers (FMM)

Future Plan

The acquisition by Frencken provides synergistic benefits to both companies as it allows Penchem to leverage on Frencken’s global market access, reaching a larger customer base. It also helps to strengthen the financial position of Penchem for the company to be more aggressive and bolder in exploring and expanding its business.

Penchem is already the market leader in providing the adhesive solutions in some industry sectors. As the technology continues to evolve rapidly, the company will ride the wave and continue to bank on its innovative and technical competencies to create breakthrough solutions. Penchem’s vision is to become the established adhesives and materials leader and continuously enabling its advanced solutions and technologies to support the customers to be the market leaders.

“Bonding Technologies Together, Enabling Mutual Successes”

Written in September 2022

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.