At a Glance

| Principal Activit(ies): |

|

| Location(s): | PMT 863, Jalan Cassia Selatan 3/1, Taman Perindustrian Batu Kawan, 14110 Simpang Ampat, Pulau Pinang. |

| Number of employees: | 157 |

| Manufacturing Floorspace: | 25,517 sq. ft. |

| Core Competency(ies): |

|

| Revenue: | RM46 million (2024) |

| Certification (s): | ISO 9001:2015 Quality Management System |

| Website: | www.thmy.com.my |

| Contact Person: | Mr Ooi Can Nix Email: canix.ooi@thmy.com.my; sales@thmy.com.my |

Introduction

THMY Technologies Sdn Bhd (THMY Tech), formerly known as Testing House Malaysia Sdn Bhd and established in 2008, is principally involved in the provision of automated test solutions for E&E products, with end-use in various industries. THMY offers design, development (software), fabrication (hardware), assembly and installation of test fixtures and/or tested platforms.

THMY serves a diverse mix of industries that depend on precise and dependable testing capabilities. Their primary clientele includes organisations in the Technology, Media & Telecommunications sectors, along with the Electrical & Electronics (E&E) and semiconductor industries. They also support industrial manufacturers and healthcare providers with solutions tailored to each sector’s unique requirements.

THMY’s strategic location enables delivery of valuable services and support to customers across countries, including Singapore, Thailand, Vietnam, the Philippines, and India.

Products & Service

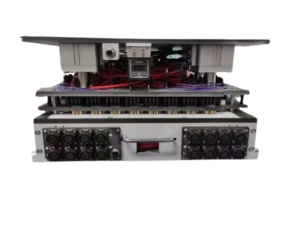

1. In-Circuit Test (ICT) Systems

THMY designs, develops, fabricates, assembles, and installs test fixtures for complete ICT solutions. The company’s test fixtures are customised to each customer’s PCBA design, the type of ICT required and the tester platform used.

| Types of Fixtures | Description |

|

Press Down Test Fixture

|

An array of pogo pins that presses the PCBA onto the fixture, establishing electrical contact with the board. |

|

Vacuum Test Fixture

|

A sealed enclosure that generates vacuum suction to hold the PCBA securely against the test fixture, enabling reliable connections between test probes and PCBA test points even when surface irregularities are present. |

|

Pneumatic Test Fixture

|

A system that uses air pressure to distribute pneumatic force evenly across the PCBA, ensuring it remains securely in place without flexing or damage. |

|

In-line Test Fixture

|

An integrated module in an automated production testing line that enables continuous or sequential testing without removing components from the process, supporting mass production and high-frequency testing. |

2. Functional Circuit Test (FCT) Systems

FCT solutions vary by application and are highly customisable to customers’ requirements. THMY designs, develops, fabricates, and assembles the tester platforms, delivering a complete, integrated FCT solution to perform the intended function.

| Category | FCT solutions |

| Test purpose | Tests whether PCBAs function according to their intended logic and functionality (e.g., power supplies, displays, inputs/outputs and communications). |

| Test coverage | Assembly-level testing: Tests the entire assembly or specific sections of the PCBA. |

| Test sequence |

Performed at the end of the production process, after component and mechanical PCBA assembly. Carried out after ICT. |

| Tester platforms | Customised needed. |

| Advantages | Thorough check of the PCBA’s performance and functionality and verifies the complete operational capability of the PCBA. |

3. Industrial Automation Solutions

Industrial Automation Solutions involve the use of specialised software and hardware tools to control test execution, monitor processes, and compare actual results against expected outcomes. By automating repetitive but essential tasks, these solutions enhance existing testing processes and make possible additional checks that would be difficult or time-consuming to perform manually.

THMY designs, develops, fabricates, assembles, and installs customised machinery and equipment for industrial automation. The company’s solutions integrate hardware such as robotics, conveyors, and sensors with advanced control systems and automation platforms. This combination streamlines workflows, minimises human intervention, and replaces inefficient manual steps with efficient, reliable processes.

Phantom Series

Automates finished-goods assembly inspection for quality control purposes.

3-D Scanning Machine

- Build Mechanical Modelling Digital Data

- Featuring in Design Validation

- Featuring in 3-D Model Printing

4. Maintenance & Repair Service

THMY offers maintenance and repair services which includes under warranty service and post-warranty service as part of after sales services.

Future Plan

- Construction of new factory

- Purchase new machinery and equipment

- Enhance solutions through D&D and R&D expenditure

- Set up new support and maintenance office

Achievements & Awards

|

Best Cooperation Partner 2024   |

Milestone: Initial Public Offering Recognition   |

Recognition: Appreciation from Universiti Sains Malaysia (USM)   |

Written in November 2025

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.