TCS Engineering & Automation Sdn. Bhd.

At a Glance

| Principal Activit(ies): | Advancement & facilitation in medical & PCB/PWB processing line |

| Location(s): | Bukit Minyak Industrial Park, Penang Malaysia |

| Number of employees: | 30 |

| Manufacturing Floorspace: | 10,000 sq.ft. |

| Revenue (2022): | RM10 million |

| Certification(s): | ISO 9001 : 2015 |

| Core Competency(ies): |

|

| Website: | www.tcs-engineering.com.my |

| Contact Person: | Mr. CS Tung Email: cstung@tcs-engineering.com.my |

Introduction

Established in 2006, TCS Engineering & Automation Sdn. Bhd. (TCS) is a one-stop centre for precision engineering and metal fabrication based in Penang, Malaysia.

The company’s core businesses are from the industries of telecommunication, medical, automobile, consumer electronics and printed circuit board (PCB)/ printed wiring board (PWB). Serving customers across various industries, TCS is well experienced in material selection (specialised in material characteristics for various chemical processing wet line and components), and third party lab test for material safety data sheet (MSDS).

Product & Services

Amongst a myriad of capacities, TCS specialized in the manufacturing and supplying of engineering solutions as well as the custom fabrication and supply of all kinds of metal related products, such as frame works, machining parts, stainless steel or mild steel base products, etc.

The company’s solutions are separated into both physical products and customized services:

- Physical products: TCS is renowned for fabricating exactitude and quality semi and high precision component parts. The company also devises chemical processing machine parts and plating machine components, meeting the high standard requested by its clients in terms of all form factors and other physical specifications of components.

- Customed services: TCS’ decades of industry experience and technical expertise enabled them to walk customers through the entire process from planning to design, installation, execution, handling of equipment, loading/unloading in process parts, modification and improvement of plating line etc., in a streamlined manner.

TCS’ Precision Machining & Processing Line Equipment List

| Machine Type | Model |

| Welding Facility | WIM/HPT |

| Shearing Machine | Sunfluid |

| CNC Milling Machine | Doosan, First, Hartford, Trident |

| Bending Machine | SMA |

| Milling Machine | 3HP |

| Turning Machine | CY 1870 |

| CNC Lathe (Turn & Mill) | Samsung |

| Engineering Plastic Rod Welding | GF/ Leister |

|

|

| Engineering Plastic Welding | CNC Milling Machine Facility |

|

|

| Welding Facility | CNC Turning Facility |

TCS’ Metrology Equipment List

| Machine Type | Model |

| Caliper | Mitutoyo |

| Micrometer | Mitutoyo |

| Ball Gauge | Mitutoyo |

| Height Gauge | Vertex |

| Tripod Laser/Floor Laser (on site for machine setup) |

Bosch |

| Granite Table | Din 876 Grade 00 |

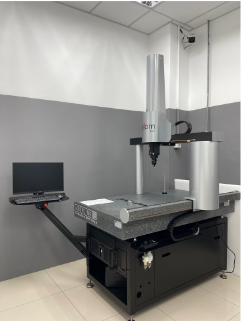

| CMM QC Checking Machine | Axiom |

| Image Dimension Measuring | Keyence |

|

|

|

| CMM QC Machine | Keyence Vision QC | QA/QC Lab |

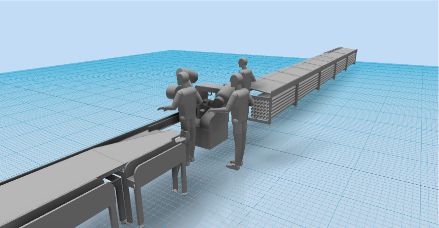

TCS’ Medical Processing Line Equipment Setup – Tube Draw for Advance Surgical Segment

| Equipment Type | Description |

| Experienced in setup & turnkey project for tubing process | TCS is able to fulfill every setup requirement, mainly on mechanical, electrical and equipment tasks during the setup of new plants or facilities for medical processing production line. All equipment, components and parts were manufactured according to ASTM standards.

Among the tubing processes available are:

|

| Machine setup (turnkey project) |

|

| Medical tubing processing line setup | Collaboration with counterpart team from the US to design and fabricate tubing processing line. OSHA & ASTM compliance requirements applied. |

| Localized in process components or machine parts |

|

TCS’ Medical Processing Line Equipment Setup – Wire for Cardiovascular

| Equipment Type | Description |

| Experienced in setup & turnkey project for wire process |

|

| Dryer oven for grinding wire | Custom made dryer oven for cardiovascular wire. Consistent temperature inside the chamber resulting optimum drying process for small wire application. |

|

|

|

| Straightening Machine | Cross Roll Derodder Bench | Dryer Oven |

TCS’ PCB Processing Line Equipment Setup

| Services | Description |

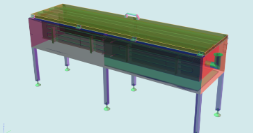

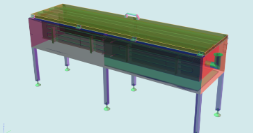

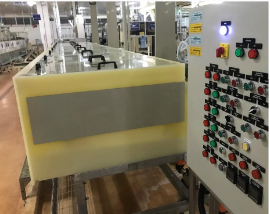

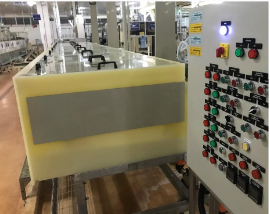

| Machine setup and piping installation on PCB/PWB plating machine (turnkey project) | Horizontal plating, electroless copper plating and desmear machine. Piping connection type range from Stainless Steel 304/316L, PVC, PP, PPN and even PVDF. Fabricate plating line spare parts. In cooperation with oversea machine maker for local machine setup.

Clientele:

|

|

|

| Horizontal PCB Machine | Horizontal PCB Machine |

|

|

| Cleaning Tank | Acid Tank |

TCS’ PCB Processing Line Components

| Plating Machine Components | Description |

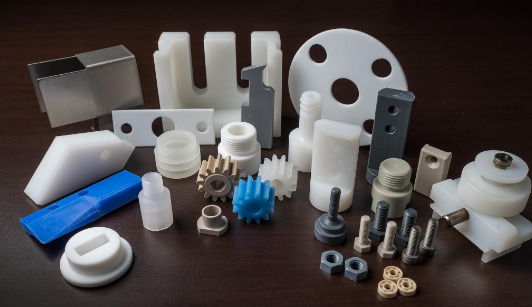

| Various kind mechanical parts for plating machine, etching machine, desmear machine & other kinds of chemical processing machine | High precision components made from various kind of engineering plastic material. Range from PVC, PP, PTFE, PEEK, PVDF, UHMW PE, MC Nylon, Carbon Fibre with coating, Titanium Grade T1 or T2, SUS 304/316/316L/SUS 630 and etc. |

|

|

|

| Engineering Plactic Components for PCB Machine | Engineering Plactic Components for PCB Machine | Precision Parts |

Future plans

Going forward, TCS aspires to improve its existing capabilities, provide better design, supply and fabrication services for complex component parts in customers’ custom-made projects. The company strives to ensure deliveries that are environmentally friendly, allow better cost saving and capable of helping customers to improve their production speed and overall efficiency.

TSC aims to be a holistic solutions provider, especially in the contract manufacturing sector in assisting its worldwide customers to strategize and fabricate high volume products with immaculate quality control. The company is also apportioning the attention into enhancing its services in the field of medical parts manufacturing, by at least 25% increment, mainly on machining parts and equipment for off-line and on-line production.

Written in Mar 2023

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.