Ideal Vision Integration Sdn. Bhd.

At a Glance

| Principal Activity(ies): |

|

| Location(s): | Setia Spice Canopy, Bayan Lepas, Penang, Malaysia |

| Number of Employees: | 30 – 50 |

| Manufacturing Floorspace: | 8,000 sq. ft. |

| Core Competency(ies): |

|

| Website: | https://www.idealvision-int.com/ |

| Contact Person: | Edmund Yuen Email: sales@idealvision-int.com |

Introduction

Established in 2013, Ideal Vision Integration is a company based in Penang, Malaysia that provides innovative, reliable and outstanding machine vision, system integration and software solutions in various industries such as semiconductor, medical, automotive and packaging. The company’s core products include Automated Optical Inspection (AOI) system for wire bond, wafer and IC package, among others.

With a proven track record of successfully delivering reliable solutions over the past decade, the company is serving clients across multiple industries, such as Original Equipment Manufacturers (OEM), Electronics Manufacturing Services (EMS) providers and Semiconductor Outsourced Assembly and Test (OSAT) players. The customer base spans across Malaysia, China, Philippines, Vietnam, Thailand, Singapore, Europe and United States.

Holding on the values of reliability, efficiency, continuity and sincerity, the company strongly emphasizes on research and development, while keeping in pace with the latest technology to continuously develop turnkey solutions which fulfil clients’ requirements, i.e. to optimize their manufacturing processes, reduce production costs, increase productivity and product quality.

Products and Services

1. JӒGER® Vision Software

JӒGER® Vision Software is an innovative machine vision platform that provides high flexibility and integration ability for most of the inspection applications in various industries.

As Jäger® Vision is designed for the flexibility in configuring various inspection task, it can be integrated into various inspection machines to perform high speed automated tasks like defect pass/fail detection, part positioning, part identification, advanced measurement etc. Jäger® Vision is used in various industries such as semiconductor, medical, automotive and packaging.

In semiconductor industry, Jäger® Vision has been integrated into various automated optical inspection (AOI) machine for the inspection of lens, wafer, package, sealing, casting, wire bond, epoxy, solder, flux and etc.

Features of Jäger® Vision:

- High Flexibility

- High Integration Ability

- Image Pre-Processing Capability

- User Friendly Interface

- High Compatibility Mapping

- Configurable Mapping Feature

- 3D Inspection

- Artificial Intelligence – AISCHÜTZE (optional)

A generic, fast and flexible vision platform

2. HDCompozite™ Technology

A patented 3D technology using high-definition composite model that enables topographic analysis, measurement and inspection for most of the material surfaces such as wafer bumps, wire bonds, component height and etc.

HDCompozite™ is a technology breakthrough for wire bond inspection as it not only overcomes the wire bond inspection limitations in the semiconductor industry, but also provides a comprehensive model that allows a thorough analysis on the wire bond, die and object’s height profile and defects. The model consists of a full 3D height profile with the surface texture overlaying on it. The generated HDCompozite™ will be processed by Ideal Vision proprietary JÄGER® Vision platform for the best detection capability and classification.

Key Benefits:

- High Accuracy Object/ Surface Height Measurement

- Enhanced Defect Detection and Classification with Jäger® Vision & AI engine

- Outstanding Defects Detection Capability

3. AISchütze™

The company’s AI platform leverages the latest deep learning technology and delivers comprehensive solutions to even the most challenging factory automation inspections. Compared to the conventional visual inspection solutions, it is the ideal solution for detecting and classifying defects that are complex in nature, while improving efficiency. With AISchütze Technology (AI), the deep learning algorithm will assist in the identification of the most intricate defects on the products.

Ideal Vision’s deep learning technology

Besides supplying software solutions and integration services, Ideal Vision Integration also innovated machines designed for automated visual inspection. These machines are known as the Automated Optical Inspection (AOI) machines, and they are powered by the Jäger® Vision. The machines are used to check the quality of wire bonds, wafers, packages, IC, castings, and others.

4. The V Series: Advanced Wire Bond AOI Machine

Advanced automated wire bond inspection system that integrates high-resolution camera and latest technology of optics and illumination. With configurable transport options, various substrate or lead frame characteristics and sizes are reliably inspected.

Ideal Vision’s patented HDCompozite™ combines both 2D imaging and 3D metrology to deliver an exceptional inspection for wire and die height profile. The system is powered by JÄGER® Vision software that designed for high-speed and precise vision inspection application.

Critical wire bond defects such as lifted stitch, lifted bond, crossed wire, and wire sagging can be identified and measured precisely.

Features:

- Modular Design

- Support Various Input / Output Loading

- Support In-Line Integration

- Image Processing Capability

- JӒGER® with Comprehensive Vision Inspection Tools

- HD Compozite™ 3D Inspection (optional)

- Artificial Intelligence – AISCHÜTZE (optional)

- Reject Station (optional)

Defect Detection:

Wire Bond Inspection

- Missing

- Broken

- Swaying/Sagging

- Double/Extra

- Stitch/Ball Bond

- Wire Loop (Optional with 3D Module)

- Others

Package Inspection

- Cosmetic (Crack/Chipping/Scratch/Contamination/Foreign Particle)

- Marking Quality

- Others

Die Inspection

- Position

- Cosmetic (Crack/Chipping/Scratch/Contamination/Foreign Particle)

- Epoxy Glue Coverage

- Epoxy Height Profile (Optional with 3D Module)

- Others

5. The W Series: Intelligent Wafer AOI Machine

Intelligent Wafer AOI Machine provides a high throughput and reliable inspection system for defects detection on various types of wafers. It is equipped with high resolution colour 2D imaging and fully automated wafer handling mechanisms.

Ideal Vision’s patented HDCompozite™ combines both 2D imaging and 3D metrology to deliver an exceptional inspection for bump height as an optional enhancement. The system is also powered by JÄGER® vision software that designed for high speed and precise vision inspection application.

Features:

- Modular Design

- Image Processing Capability

- JӒGER® with Comprehensive Vision Inspection Tools

- Automatic Loading and Unloading

- Wafer Pre-Alignment

- Support Dual Inspection Station

- SECS/GEM Ready

- HD Compozite™ 3D Inspection (optional)

- Artificial Intelligence – AISCHÜTZE (optional)

Defect Detection:

Die

- Positioning

- Cosmetic (Crack/Chipping/Scratch/Contamination/Foreign Particle)

- Marking

- Others

Bump

- Bump Height (Optional with 3D Module)

- Present

- Positioning

- Damage

- Others

6. The PSV Series: Post Seal Vision Inspection Handler

A dual track designed handler with high-speed inspection performance, supports up to 6 vision systems that boost up inspection capabilities such as package inspection, lead inspection, cosmetic inspection, tape seal inspection and bottom tape inspection.

Ideal Vision’s system is designed to provide easy and fast changeover for different type of carrier tape width with motorized track module. The system is powered by JÄGER® Vision platform that enhance the inspection flexibility and accuracy.

Features:

- Dual Tracks Design

- Support up to 6 Vision Systems

- Motorized Tape Track

- JӒGER® with Comprehensive Vision Inspection Tools

- Auto Labelling Reject Station

- High UPH up to 100,000 * (Subjected to carrier tape width and pocket pitch)

Defect Detection:

Package Inspection

- Cosmetic (Crack/Chipping/Scratch/Contamination/Foreign Particle)

- Marking Quality

- Others

Sealing Inspection

- Broken Seal

- Uneven

- Sealing Width

Bottom Carrier Tape Inspection

- Pocket Damage

- Dented

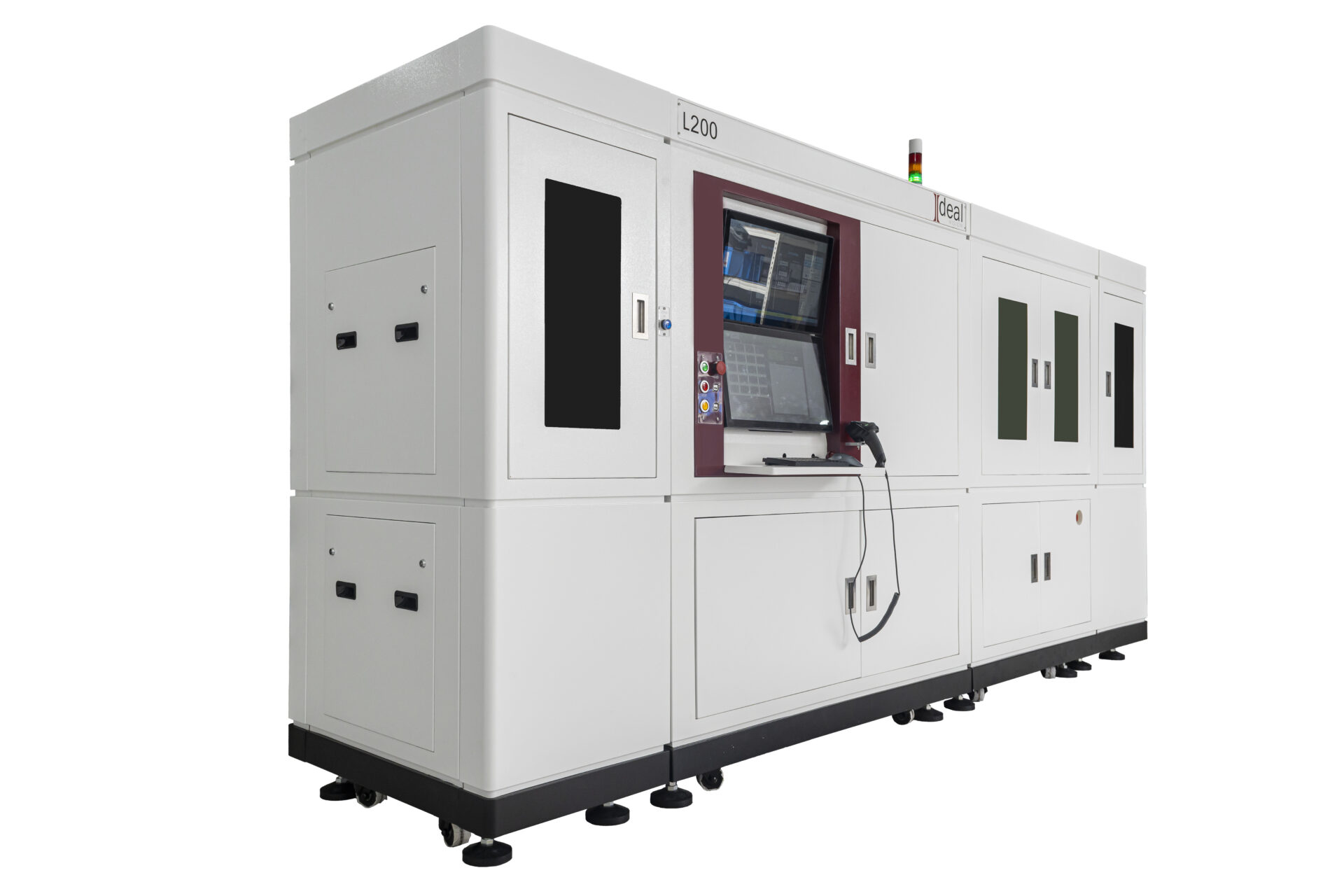

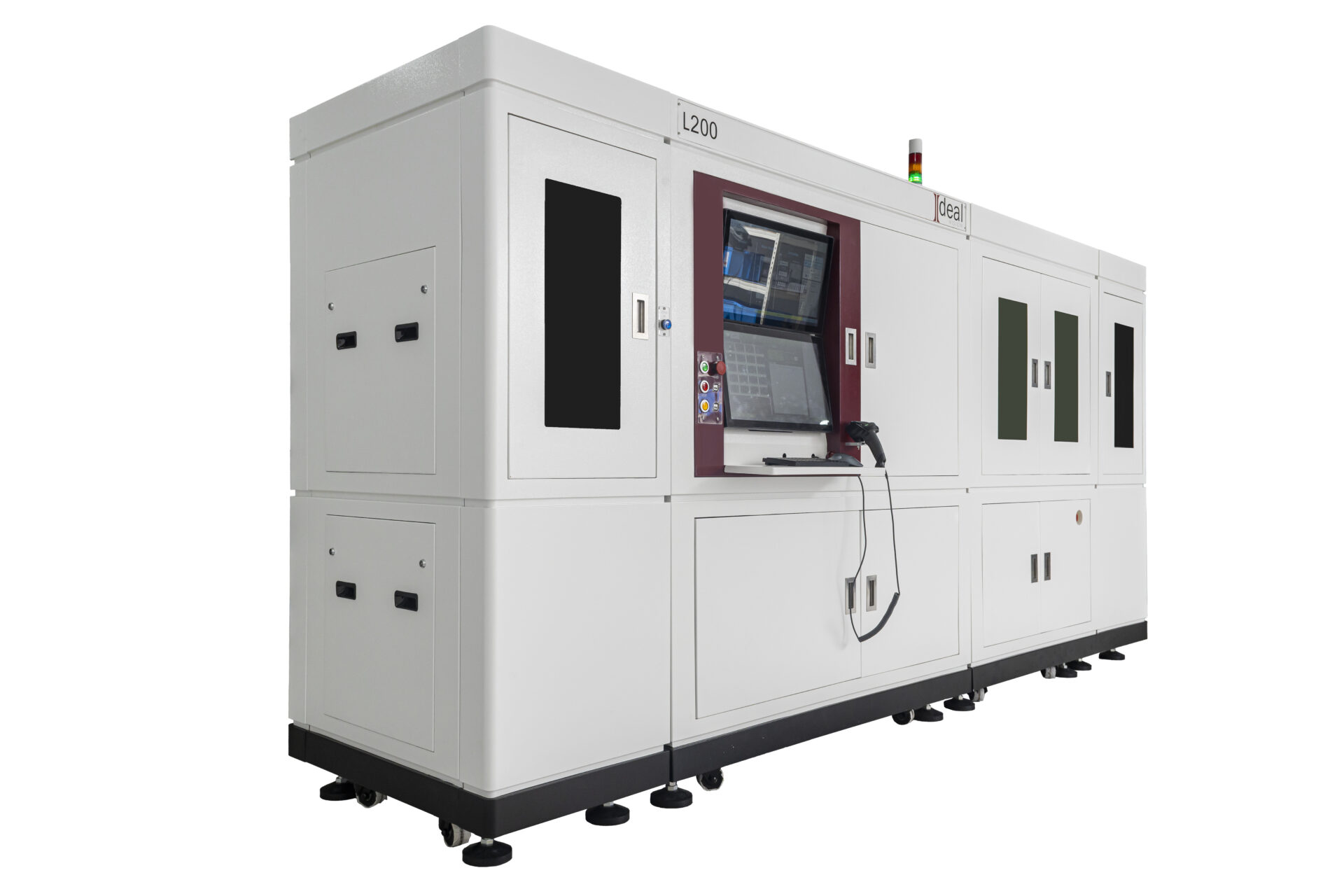

7. The STORM Series: High Speed Substrate AOI Machine

STORM Series is a high-speed automated optical inspection system that perfectly integrating Line Scan Imaging with latest technology of optics and illumination.

The dual inspection station enables fast scanning for top and bottom substrate with the high precision gantry system. With configurable transport options, various substrate characteristics and sizes can be reliably handled.

The system is powered by JÄGER® Vision software that designed for high speed and precise vision inspection application. An optional AI Engine, AISCHÜTZE™ provides deep learning-based algorithm to enhance the detection and classification on most of the defects that are complex in nature.

Features:

- Modular Design

- Support Various Input / Output Loading

- Support In-Line Integration

- Image Processing Capability

- Comprehensive Vision Inspection Tools

- Artificial Intelligence (optional)

- Laser Mark Station (optional)

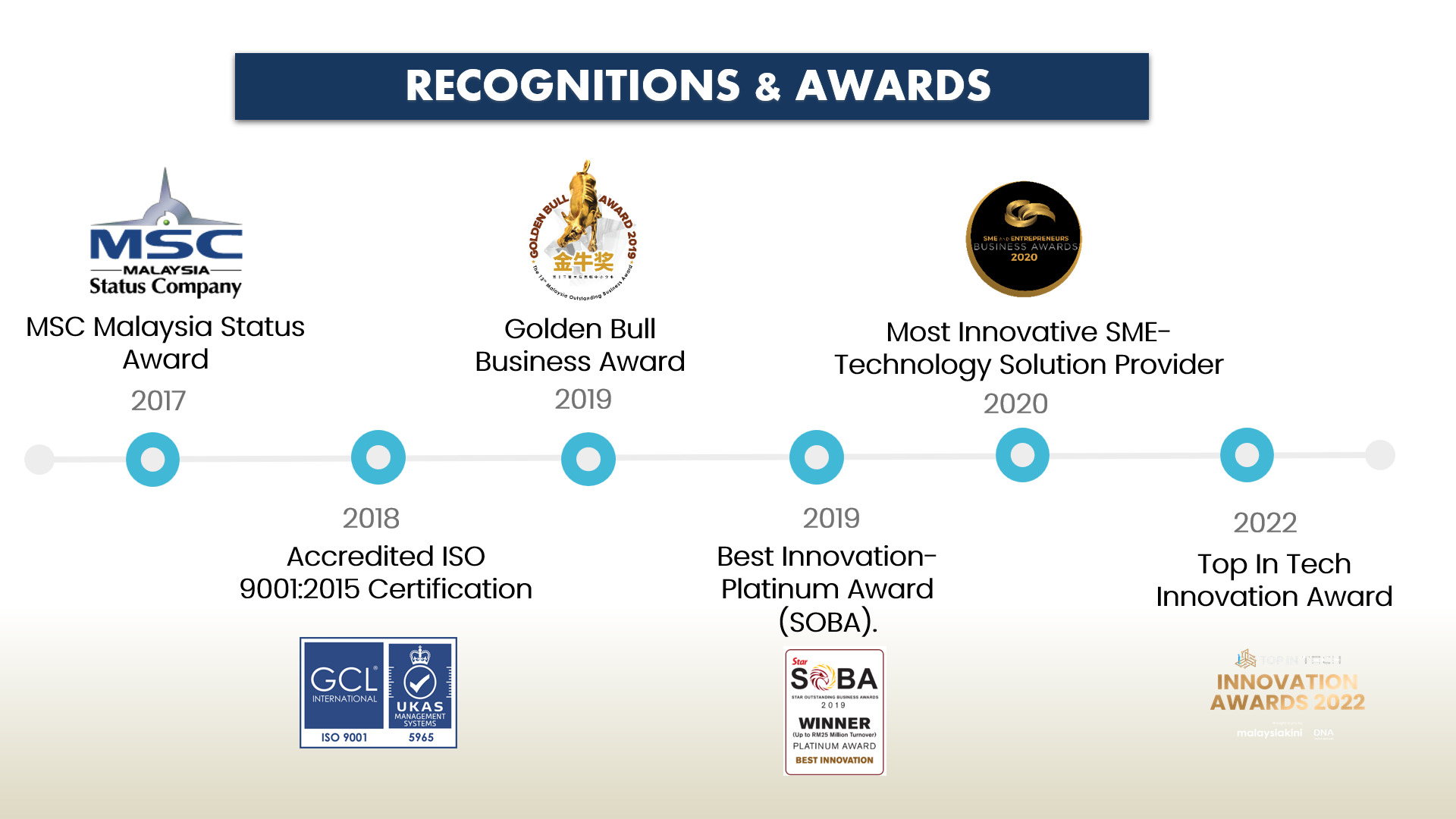

Achievements & Awards

Written in Sep 2022

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.