At a Glance

| Principal Activities: | Precision engineering services support provider |

| Location(s): | Prai and Penang Science Park, Simpang Ampat (2024) |

| Number of employees: | 150-200 |

| Manufacturing Floorspace: | Current: 20,000 sq. ft. 2024: 78,000 sq. ft. 1st phase, 60,000 sq. ft. 2nd phase |

| Core Competencies: |

|

| Revenue: | USD 10 million per annum |

| Certification (s): | ISO 9001:2015 |

| Website: | www.uistech.com.my |

| Contact Person: | Mr Teh Chin Tuan Email: ctteh@uistech.com.myMr Simon Tan Yeow Huat Email: simontyh@uistech.com.myMr Ivan Lan Hong Tat Email: IvanLan@uistech.com.my |

Introduction

UIS takes pride in the profound expertise demonstrated by their professional engineering team. Committed to innovation, UIS consistently pushes boundaries to cater to the diverse needs of valued clients. The unwavering dedication by UIS to excellence is rooted in the relentless pursuit of quality and a comprehensive suite of services that reaches beyond the conventional realm of CNC machining and precision parts manufacturing.

With over 20 years of experience, UIS has assembled an experienced and professional engineering team equipped with the latest design software, including Delcam, Mastercam, SOLIDWORKS, and AutoCAD, to seamlessly meet customer requirements for precision-machined parts and component fabrication. UIS transforms conceptual ideas into reality, utilising their knowledge grounded in the latest process engineering services developments.

By incorporating cutting-edge Japanese machining technology, specifically Mazak, Okuma, STAR, and FANUC CNC, UIS confidently offers customers superior control over machining tolerances. UIS’s proficiency extends to reverse engineering, providing efficient solutions for time and cost savings. To meet the demands of the surface finishing market, UIS has invested in high-quality lapping and polishing tools from Germany.

With a commitment to innovation and excellence, UIS specialises in providing project-based end-to-end automation services for a wide spectrum of industries. UIS’s team of skilled engineers and technical experts collaborates seamlessly to design and implement bespoke automation solutions that optimise efficiency, reduce costs, and elevate overall performance. The company is dedicated to shaping the future of industries through cutting-edge automation technologies.

UIS’s specialisation is underscored by certifications, including ISO9001:2015, and recognition from diverse industries globally, such as semiconductor, automation, solar, oil & gas, electronics, and mechanical, among others.

Products & Services

1. Contract Manufacturing

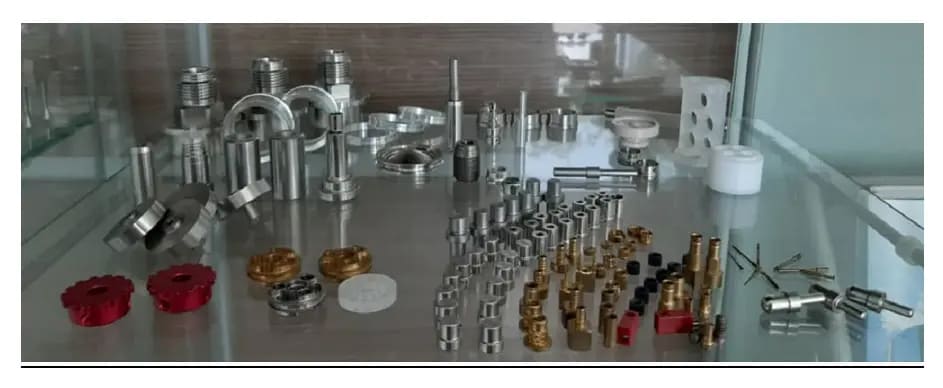

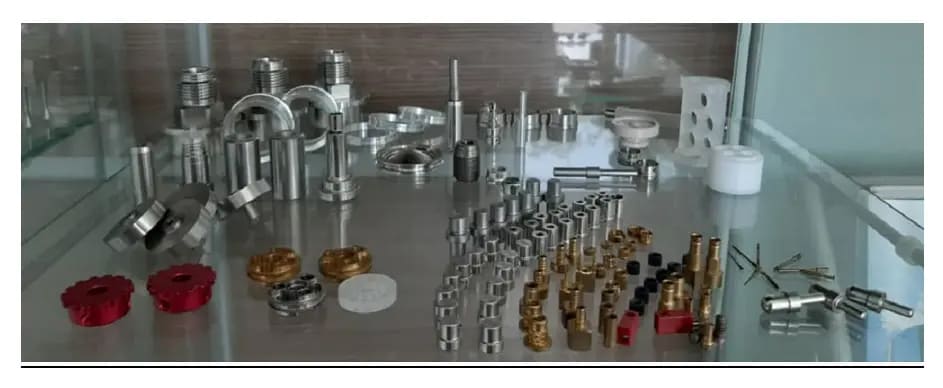

The well-equipped facility in UIS boasts cutting-edge machinery, comprising a total of 66 units across various types including:

- CNC Turn/Mill;

- CNC Horizontal;

- CNC Turning;

- CNC Milling; and

- Auto Lathes.

These state-of-the-art machines enhance capabilities and enable UIS to deliver precision and efficiency in manufacturing processes.

To meet the diverse requirements of clients, UIS specialises in machining various materials, including:

- Engineering Plastics: PBT, PPS, PET, PEEK, Teflon, Delrin, and more

- Metals: Stainless steel (303, 304, 316, etc.), aluminium (5 series, 6 series, 7 series), hardened steel, alloy, and more

In order to enhance capabilities and better serve clients, UIS has made strategic investments in advanced equipment, including a mirror polish machine and an ultrasonic cleaning facility. These additional facilities allow UIS to provide comprehensive support for clients by ensuring precision and quality in machining processes.

UIS’s commitment revolves around delivering high-quality products across a diverse spectrum of materials, tailored to meet the unique specifications by each client.

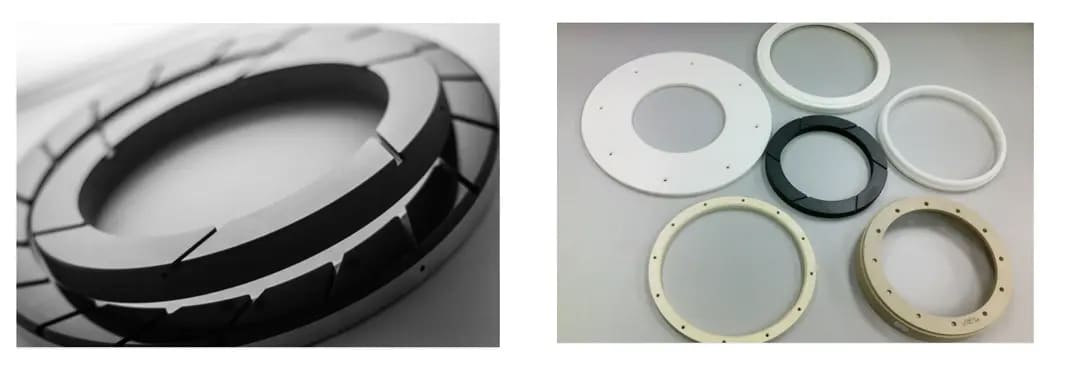

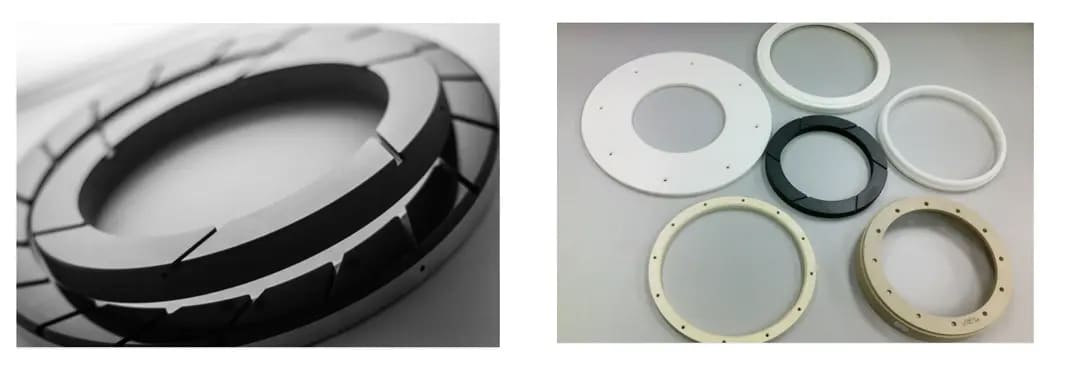

2. Chemical Mechanical Polishing or Planarisation (CMP) Guide Ring

Specialising in CMP tools solutions, UIS excels in the fabrication of CMP retaining rings, utilising various engineering plastics available in the market, including PPS, PEEK, PBT, and PEEK with +40% carbon. To enhance after-sales service and continually improve products, UIS has established an expert engineering team dedicated to R&D, issue troubleshooting, and providing technical support for customers.

UIS’s proficiency extends to engineering rework, refurbishment services, part modification, and design for all types of CMP retaining rings. This commitment to excellence underscores UIS’s dedication to meeting the evolving needs of clients.

3. Wire Guide Roller Polyurethane Coating Services

One of UIS’s core businesses involves providing PU coating and grooving services for Wire Guide Rollers equipped in wire saw machines. UIS employs state-of-the-art dispensing machines for the Polyurethane (PU) mixing process. This advanced technology enables UIS to consistently produce high-quality PU coatings for wire guide rollers. Importantly, UIS exclusively uses PU materials known for their high quality and reliability.

Advantages:

- Consistent results and high performance

- Ensuring top quality

- Eliminating air entrainment causing bubble issues

Achievements and Awards

Future Plan

UIS is thrilled to announce an expansion from their current plant location at Prai (20,000 sq. ft.) to the Penang Science Park, with a substantial increase of their operational space to 130,000 sq.ft.. The expansion will be carried out in phases, with the first phase encompassing 78,000 sq. ft. and the second phase at 60,000 sq. ft..

Through rapid expansion, the company has extended its services to various sectors, including semiconductor, automation, solar, oil & gas, electronics, and mechanical. Positioned as a dynamic and swiftly advancing company, UIS anticipates a twofold growth in terms of business size in the coming years.

Written in December 2023

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.