At a Glance

| Principal Activit(ies): |

|

| Location(s): |

|

| Number of employees: | 50 |

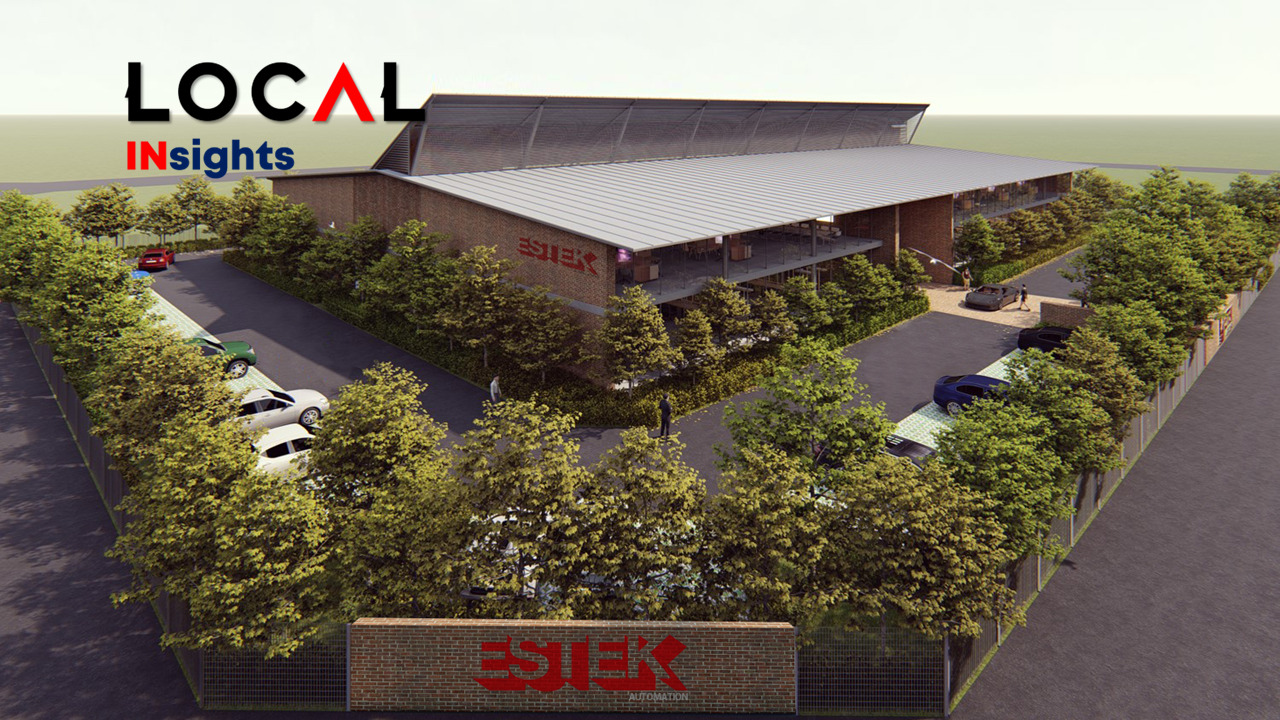

| Manufacturing Floorspace: | 6,300 sq. ft. (Bayan Lepas, Penang, Malaysia) 65,000 sq. ft. (Batu Kawan, Penang, Malaysia – 2024) |

| Core Competency(ies): |

|

| Certification (s): | ISO 9001:2015 |

| Website: | www.estechs.com |

| Contact Person: | Mr. Jacky Lee (CEO) Email: jacky@estechs.com |

Introduction

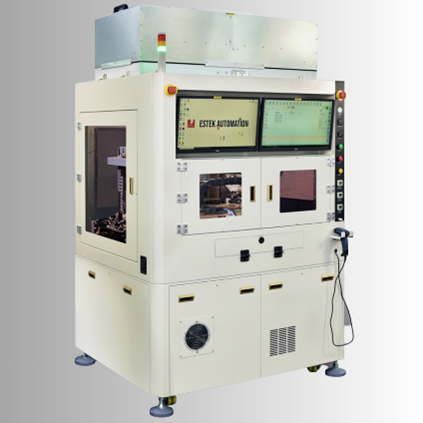

Established in Penang, Estek Automation has over the years grown as an innovative vision and turn-key solution provider. The company specialises in customised equipment incorporated with in-house software, enabling precise and reliable vision inspection for various materials, quickly and cost- effectively.

Estek Automation also provides user-friendly comprehensive solutions for product traceability, which has effectively replaced traditional manual inspection methods, with a very short payback period. The company’s clientele spans across diverse industries such as semiconductor, medical, photonics, automation, packaging, communication, automotive and many others.

The company’s rapid growth in the industry has enabled them to establish their presence across Asia Pacific, with sales and service support representatives in Singapore, Taiwan, Philippines, China, Thailand, Korea as well as the North America region, USA.

Notably, Estek Automation has successfully developed their technologies in wafer inspection, flexible chip/package sorter, microscopic wafer inspection and 2D/3D wire bond inspection.

Products & Services

EMS10 – Multi Carrier Die SorterFully automated and high-speed die sorter, it can handle any wafer size up to 300mm. Configurable for multi-carrier: up to 300mm wafer, JEDEC tray, waffle pack, gel pack, photon ring (hoop ring), and tape and reel.

|

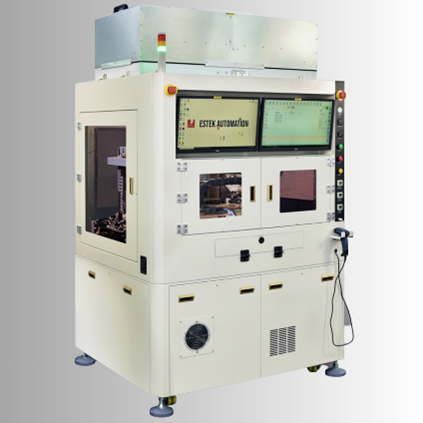

| ELS 3600 – Lens Sorter & Inspection System

Fully automated linear pick and place lens sorter for high accuracy placement position. It is designed to cater for smartphone, AR/VR, automotive, and any optics-related application. Equipped with Pick & Place Robot (PPR) with built-in Z, theta and force sensor. With this feature, the system is able to pick up sophisticated and delicate parts with lightning speed without any damage.

|

|

|

| EDS15 – Wafer to Wafer Die Sorter

Fully automated and high-speed die sorter, it can handle any wafer size up to 300mm and can reconstruct wafers to different output form factors.

|

|

| EWS300 – Microscopic Wafer Inspection

With years of research and development, the EWS300 was developed based on a decade of experience in automation process, resulting in the development of our state-of-the-art product, with groundbreaking features that bring the product to a new level of simplicity, reliability, and speed for automatic optical inspection solution. With sub-micron resolution, it has the capability to inspect down to 1um defect size.

|

|

| EWS100 – Wafer Vision Inspection

Wafer inspection platform that leverages on Estek’s innovative vision technology. It delivers high-throughput and precision wafer-level and tile inspection up to 10um detection capability. It is also equipped with skeleton wafer inspection and die counting features.

|

Future Plan

Estek Automation is committed to develop and understand the technologies behind the product that is made in order to enhance customer experience when their equipment is in use. Additionally, the company will continue to enhance their solutions and capabilities to reinforce their existing core business, with an aim to become one of the leading solution providers in image processing (vision inspection) and automation solutions in the future.

Written in August 2023

Disclaimer:

Every effort is made to provide accurate and complete information in this article. However, InvestPenang makes no claims, promises or guarantees about the accuracy, completeness, or adequacy of the contents and expressly disclaims liability for errors and omissions of this article.