Building Back Better: A Sustainable, Resilient Recovery for Malaysia’s E&E Industry

Dec 28 – The year 2020 has all the makings of a momentous year. The Covid-19 outbreak has sent global industries and economies into a tailspin, posted significant threats to the healthcare system, severely disrupted the supply chain and dampened consumer spending.

In Malaysia, the Movement Control Order (MCO) kicked off on 18th March, and curtailed economic activities severely. The Electrical & Electronics (E&E) industry was heavily impacted by the lockdown which caused manufacturing facilities to come to a grinding halt and brought about major disruptions to the supply chain.

Whilst these volatile times have put the industry through a stress test, the silver lining lies in the emergence of opportunities for new ways of thinking and doing things. This includes finding new strategies to revitalize, restructure and rebuild towards a sustainable future.

Amidst this crisis, we have seen captains of the industry formulate strategies to adapt and overcome the uncertainties posed by the pandemic. These leaders have adjusted to the disruptive events with speed and agility and collaborated with trusted partners to find solutions that contribute to the recovery of their organizations, the industry and ecosystem.

Voices from the industry

Building a better post-pandemic world requires leaders to imagine the unthinkable. The following leaders expect far-reaching changes in the coming year, but critically see opportunities to shape the industry for the better. Below is a snapshot of how 2020 has shaped out for them and the post-pandemic future they envision.

Ang Hee Lai, Vice President & Managing Director, Renesas Electronic (Penang) Sdn Bhd

2020 has been a challenging year for Renesas in many aspects – we have had to familiarize ourselves with new ways of working and operating our business. Through these challenges, we realized the importance of having a solid business continuity plan and a diverse source of supply chain partners to mitigate unforeseen circumstances such as shortage in supply or in the event where our manufacturing facilities have to be shut down. All in all, the pandemic has taught us what it’s like to be more agile and resilient, as individuals and as an organization.

Renesas’s immediate priorities include building on our current platform that has kept us competitive in the marketplace. We will fortify our business continuity plan, optimize Work From Home (WFH) concepts, automate and build systems around WFH, including digitalization of activities using web and apps to increase productivity and efficiency.

Moving into 2021, Renesas believes that new technological innovations will continue to drive the E&E sector forward.

Firdaus Abdullah, CEO & Executive Director, SilTerra Malaysia Sdn Bhd

2020 was indeed a challenging year not only in Malaysia but globally. We were shocked when news of the MCO was announced but were relieved to hear almost immediately thereafter that semiconductor fabs were considered critical industries and therefore allowed to operate. Disruption to the supply chains hampered deliveries in and out of the country and as a result, affected delivery of our finished products, incoming spare parts, repairs and maintenance schedules.

Our lessons from the pandemic include the need for strong leadership, to maintain contact with what’s happening on the ground and to provide our teams with necessary support for them to do their best. The pandemic has sharpened our focus on what we need to do to enable our factories to deal with unforeseen circumstances. Addressing the struggles of this year will ultimately put us in a better position for 2021.

The E&E sector is less impacted compared to sectors like F&B, tourism, consumer and retail. We need to recognise that Malaysia’s E&E sector is probably one of the most resilient strongest in the world. Unfortunately, unlike Taiwan and Korea, we have not nurtured our locally developed products to international standards – this is not due to our capabilities, but rather our mindset. Therefore, more needs to be done to foster locally designed technologies to fulfil local demand which will in turn contribute to the advancement of Malaysia into the high-tech era. This will be SilTerra’s focus, moving into 2021.

Eric Chan, VP & General Manager of IOTG Customer Engineering, Intel Corporation

The pandemic has caused tremendous disruptions on manufacturing operations which in turn impacted productivity in design and development of our products. However, on the upside, it has accelerated digital transformation which in turn spurred demand for semiconductor and electronics globally.

My takeaway from this experience is the need for better preparation particularly on business continuity and contingencies for future pandemic-related disruptions or other unprecedented events. In addition, there is a need to continuously ensure the safety of our employees, to look at redundancy in areas of supply chain, logistics and workforce and not forgetting the importance of partnerships with government and industry to overcome the pandemic. These are Intel’s priorities moving into 2021, on top of establishing WFH efficiencies and application of innovations to solve pandemic-related challenges.

I’m of the opinion that the semiconductor and electronics sector will see positive growth in 2021. Having said that, we will continue to experience uncertainty around supply chain and logistics, including fallout from the US-China trade tensions and fragmentation of global trade.

Sim Hon Wai, COO, MDT Innovations Sdn Bhd

2020 started well for us with our newly established factory ramping up production of RFID inlays and business expansions into Africa, Thailand and Indonesia. However, things took a u-turn when most countries globally experienced the lock down and hundreds of thousand of dollars’ worth of contracts had to be cancelled. Despite a grim outlook in Q2, MDT received new business opportunities related to Industrial Revolution (IR4.0) initiatives and many of our businesses are speeding up due to the adoption of new technologies to circumvent the impacts of Covid.

Our priority for 2021 is to focus on business sectors that are more vulnerable and to introduce digital solutions to add value to our business processes, products and services.

MDT foresees general market recovery in 2021 with growth in the tech sector, led by Internet of Things (IoT), resulting from uptake in businesses tapping into sub sectors of IoT to improve their day to day operations. The E&E sector is a key contributor to the nation’s GDP. In 2019, the industry accounted for 6.3% of the country’s GDP and has contributed approximately RM372.67 billion in export value, representing 44.7% of all manufactured goods exported.

Chu Jenn Weng, President & CEO, ViTrox Technologies Sdn Bhd

ViTrox achieved double digit growth in 2020 amidst the Covid-19 pandemic and the ongoing trade tension between US and China. We experienced supply chain disruptions on the onset of the MCO but managed to adjust our work arrangements quickly, to safeguard our people’s health and safety, whilst simultaneously reacting swiftly to customers’ needs.

At Vitrox, we believe in staying nimble and agile. Our philosophy was heavily tested this year but we were quick to adapt to change, remaining resilient in the face of uncertainty, which led to us rebounding quickly. Our priorities for 2021 include accelerating R&D on (IR4.0) and AI and to invest more on talent and infrastructure to enable seamless remote working.

The future outlook for the semiconductor and E&E industry in 2021 looks encouraging, with many short to long term opportunities abound for the technology equipment sectors, made possible through heavy adoption of automated manufacturing solutions regionally. In view of this, Malaysia needs to build a strong high tech equipment ecosystem to attract high value investments both locally and abroad, in addition to creating sustainable local high-tech capabilities to support high growth local industries.

Building back better

The E&E industry in Malaysia has been identified as playing a critical role in the country’s recovery and regrowth following the pandemic. The sector has shown signs of resilience to the economic turmoil and is expected to continue stabilizing in the coming months on account of demand for smart manufacturing capabilities, automation and technological innovations.

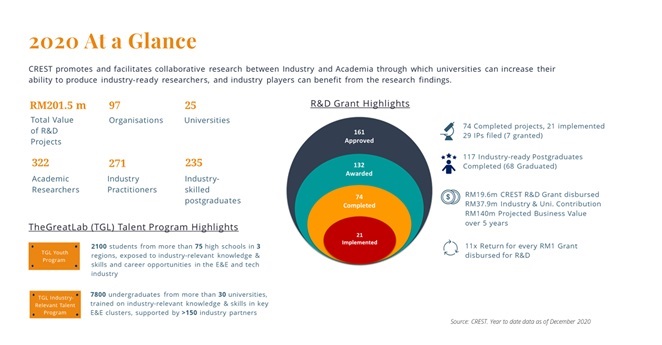

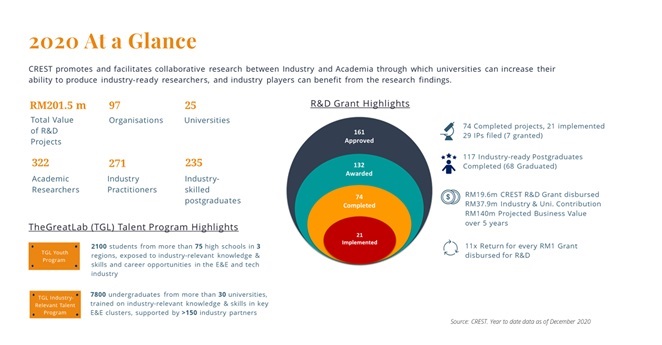

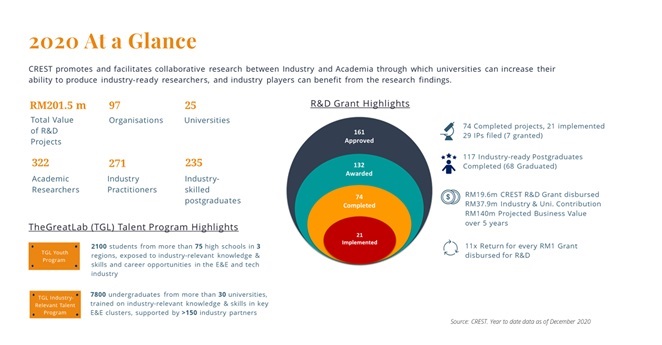

CREST (Collaborative Research in Engineering, Science and Technology Centre) believes that the E&E industry can rebound quicker, on the back of innovation and R&D efforts.

- Towards an innovation-led recovery

The centrepiece to promote recovery and quality growth during hard times is to drive innovation. The need for innovation is greater than ever, driven by new challenges that are more disruptive. History has taught us that spending on innovation must be sustained through tough times in order to better compete when recovery resurfaces.

The pandemic is putting us through an innovation stress test – it is pushing organisations to work together in new ways, to create ecosystem-wide innovation. To meet these challenges, organisations will need to innovate, collaborate, invent and redefine themselves. The rules around innovation will never be the same – this means, as a nation, we need to prioritize cross-industry collaboration to help companies break through from innovative ideas to commercial success.

- R&D, a catalyst for economic recovery

Industry leaders can make all the right moves to protect their business through the current economic shock, but their future competitive position depends largely on how they manage a single critical dimension: R&D. High-value R&D activity is critical for a faster economic recovery. Companies that are smart in R&D efforts now, can use this disruption to explore new ways of operating, improve products and gain a competitive advantage when the global economy recovers.

Year 2020 for CREST

2020 saw CREST play a key role in helping the industry re-engineer and rebound. In the early months of the pandemic, we collaborated with the government (MIDA and MITI), industry associations such as The Free Industrial Zone, Penang, Companies’ Association (FREPENCA) and Kulim Industrial Tenants Association (KITA)) and with support from industry, assisted E&E companies to navigate the challenges posed by the MCO. Being the catalytic sector that cuts across many industries, particularly in producing parts and components for medical devices, enterprise storage, cloud computing and other technological innovations, it was critical that most companies were allowed to operate during the MCO.

Hence, as a catalyst that connects with different stakeholders to collaborate and jointly create solutions for the ecosystem, we spearheaded discussions with the government and industry and implemented procedures and protocols that led to the reopening of operations and continuity of the supply chain.

Our collective success from this experience underpins the importance of collaboration to safeguard the industry and the learnings from the E&E sector is a model for other industries to emulate.

CREST as a central platform to facilitate recovery for the industry

As we move into 2021, here’s how we see CREST play a catalytic role as a central platform to facilitate recovery for the industry, in addition to building a thriving E&E ecosystem that centers on technology, research, innovation and talent.

- Collaboration

Success in the increasingly global and more competitive E&E industry relies on how we collectively leverage different stakeholders. Collaboration is key as the cost of E&E development and innovation is expensive, and no entity can do it alone. Collaboration also means leveraging resources, such as partnering with research institutions to create joint programs with academia and to draw on each other’s expertise to solve societal problems.

In this instance, CREST will continue to adopt a synergistic approach with government, academia and industry to collaborate and jointly create solutions for the ecosystem. Our partners and collaborators are change agents who assume a vital role in the growth of the R&D ecosystem. To date, we have over 90 members, 2000+ subject matter experts and 20+ startups that contribute towards building a vibrant ecosystem.

- Building a pipeline of industry-ready talent

The E&E industry has played a vital role in steering the curricular of the Institutes of Higher Learning. Together with the government, industry and academia, CREST is working towards ensuring that the education curriculum aligns with industry needs and is agile enough to keep E&E talents adopting new trends. This is in addition to ensuring that reskilling and upskilling of existing talent is continuously looked into, to meet the demands of today’s world.

Source: Digital News Asia